CATEGORIES

Modern Rice Milling Process

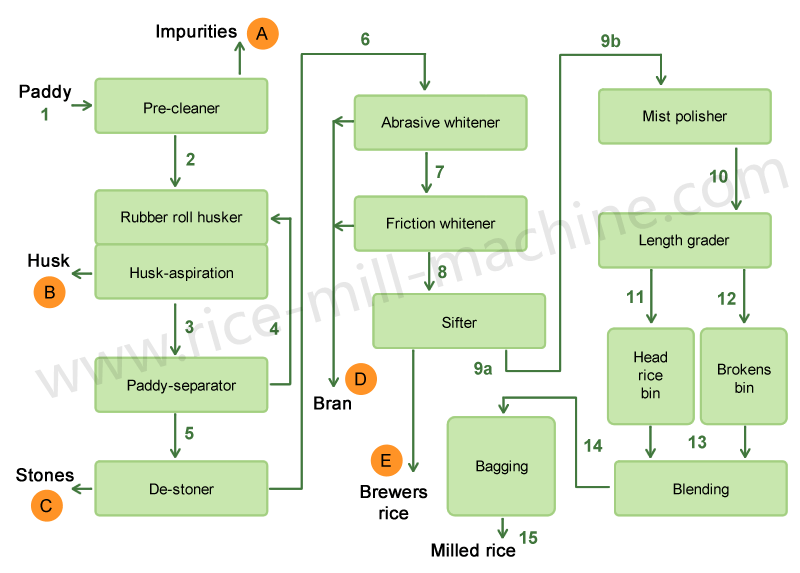

Modern Rice Milling Process can be a simple one or two step process, or a multi stage process.

The basic Rice Milling Processes consist of:

Pre Cleaning : Paddy cleaner is the most essential equipment in a rice mill, as it separates all the impurities like dust, straw, sand, clay and heavy particles of even an uneven sizes from paddy. The advantages with the paddy cleaner are that increases the life of rubber rollers and the percentage of oil in bran.

De-stoning : Separating stones from paddy.

Rice Husking : This dehusker machine is used for dehusking of paddy and removing of husk. The machine is based on centrifugal principle.

Husk Aspiration : Separating the husk from brown rice and unhusked paddy.

Paddy Separating : Separating the unhusked paddy from brown rice.

Rice Whitening : Removing all or part of the bran layer and germ from brown rice . The rice whitener is used for whitening (i.e. removal of bran) of brown rice to white rice. Through a smooth flow of rice and the efficient aspiration system inside the machine,

the rice is whitened very gently.

Rice Polishing : Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of the milled kernel.

Rice Grading : Separating small and large brokers from head rice.

Color Sorting: Remove bad rice, black rice, yellow rice, half-husked rice, etc

Blending : Mixing head rice with predetermined amount of brokers, as required by the customer.

Weighing and bagging : Preparing the milled rice for transport to the customer.

Parboiling : Helps in improving the nutritional quality by gelatinization of starch inside the rice grain. It improves the milling recovery percent during deshelling and polishing, whitening operation.

REQUEST A QUOTE

Please tell us your detailed requirements, as capacity, quantity, destionation port, etc, so that we can quote you the best price.