Home > Product > Rice Mill Plant > 100 Ton Auto Rice Mill

Rice Milling Machines

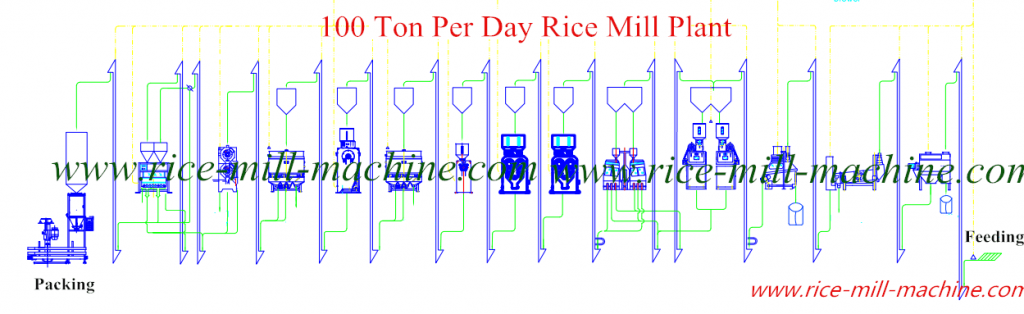

100 Ton Automatic Rice Mill Plant

This 100 ton per day Complete Set Auto Rice Mill Project systems mill the paddy in stages, and hence are called multi-stage or multi-pass rice mills, including rice cleaner,rice destoner, rice husker, paddy separator, rice whitener, rice polisher, rice color sorter, rice grader, rice packing machine, etc.

The objective of the rice milling is to reduce mechanical stresses and heat buildup in the grain, thereby minimizing grain breakage and producing uniformly polished grain. Compared to village-level systems, the system is a more sophisticated system configured to maximize the process of producing well-milled, whole grains.

100 Ton Rice Mill Machine List

| No. | Device Name | Model | Quantity | Unit |

| 1 | Drum Sieve Cleaner | HSCY80 | 1 | set |

| 2 | Vibratory Sieve | TQLZ125 | 1 | set |

| 3 | De-stoner | TQSX125 | 1 | set |

| 4 | Pneumatic Paddy Husker | MLGT25E | 2 | set |

| 5 | Double Body Paddy Separator | MGCZ46*20*2 | 1 | set |

| 6 | Emery Rice Whitener | MNMF18*2 | 2 | set |

| 7 | Iron Roller Rice Whitener | NF20 | 1 | set |

| 8 | White Rice Plan Sifter | MJP120×4 | 2 | set |

| 9 | Rice Polisher | MPG130 | 1 | set |

| 10 | Length Grader | HDJY71×2 | 1 | set |

| 11 | Color Sorter with compressor | H256CCD | 1 | set |

| 12 | Bucket Elevator | DTG26/13 | 1 | set |

| 13 | Bucket Elevator | DTG26/13 | 15 | set |

| 14 | Rice Packing Machine | DCS100 | 1 | set |

Features:

- This 100 ton complete set rice mill plant apply the latest technology of rice milling, improve the milled rice rate, reduce broken, lower temperature meters, good bran removal effect, stable mechanical performance, convenient operation and maintenance.

- Craft work can be designed specially, combined flexibly and processed into different kinds of excellet rice according to different client's need.

- It is environment-friendly inters of adopting high-effective dust collecting unit to get rif of dust.

- It covers a small area, can be designed specially according to the client's requirement.

Rice mill plant layout design, commissioning, training, technical support will be provided and rice mill machine parts are available.

Modern Complete Set Rice Milling System consist of:

- Rice Cleaning Machine: removing all impurities and unfilled grains from the paddy;

- Rice Destoner Machine: separating small stones from the paddy;

- Rice Huller Machine: removing the husk from the paddy;

- Paddy Separator: separating the unhusked paddy from the brown rice;

- Rice Milling Machine: remove all or part of the bran layer and germ from the brown rice;

- Rice Polishing Machine: improving the appearance of milled rice by removing remaining bran particles and by polishing the exterior of the milled kernel;

- Rice Grading Machine: separating small impurities or chips from the milled rice;

- Rice Length Grador: separating small and large brokens from the head rice;

- Rice Color Sorter: remove bad rice, black rice, yellow rice, half-husked rice, etc;

- Rice Blending Machine: mix head rice with predetermined amount of brokens, as required by the customer;

- Rice Packaging Machine: rice weighing and bagging: preparing milled rice for transport to the customer.

We offer automatic complete set rice mill plant from 18-500 ton per day, with high rice yield and good white rice quality.

If you're interested, pls do not hesitate to contact us to get the best cost of 100 ton rice mill project.

Other capacity rice mill price:

1 ton Rice Mill Price

2 ton Rice Mill Price

3 ton Rice Mill Price

4 ton Rice Mill Price

5 ton Rice Mill Price

REQUEST A QUOTE

Please tell us your detailed requirements, as capacity, quantity, destionation port, etc, so that we can quote you the best price.